“At Wilson & Bow, we take your branding, material selections, color choices, and style preferences very seriously because we want you to be extremely happy with your finished product.”

Selection & Customization

We begin our creative process by gathering as much information about our client as possible — collecting anything from official colors, logo, branding materials, as well as client ideas and suggestions. We work very closely with our client to determine which fabric, cloth weight, and/or woven texture is appropriate for each project. Our custom products are manufactured using high quality materials such as silk, cotton, hemp, wool, bamboo, or other exotic materials.

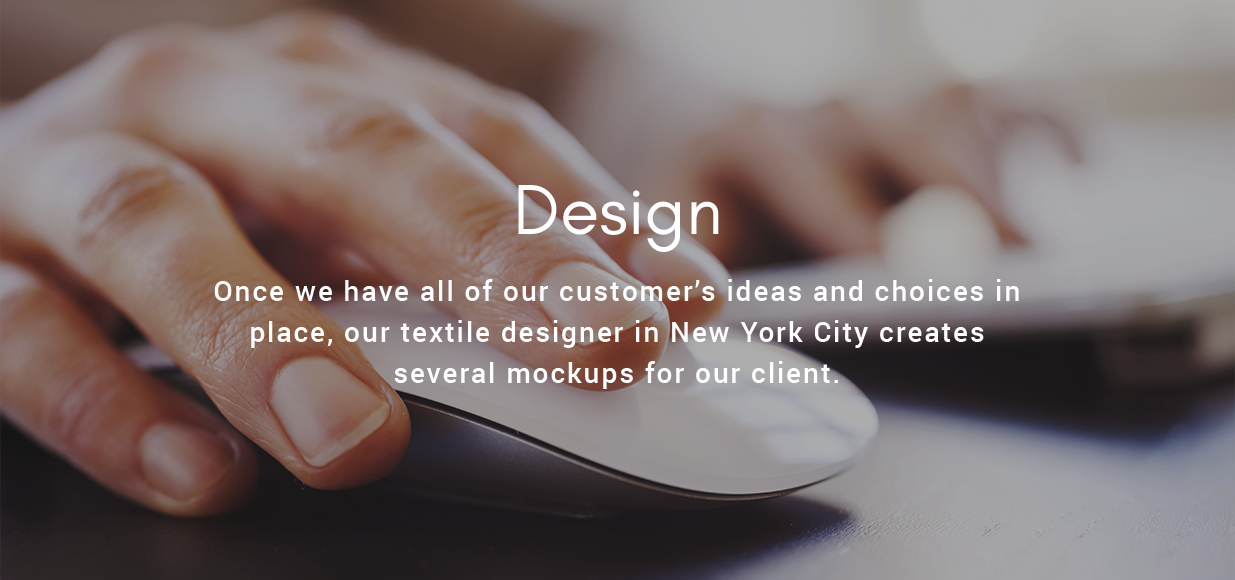

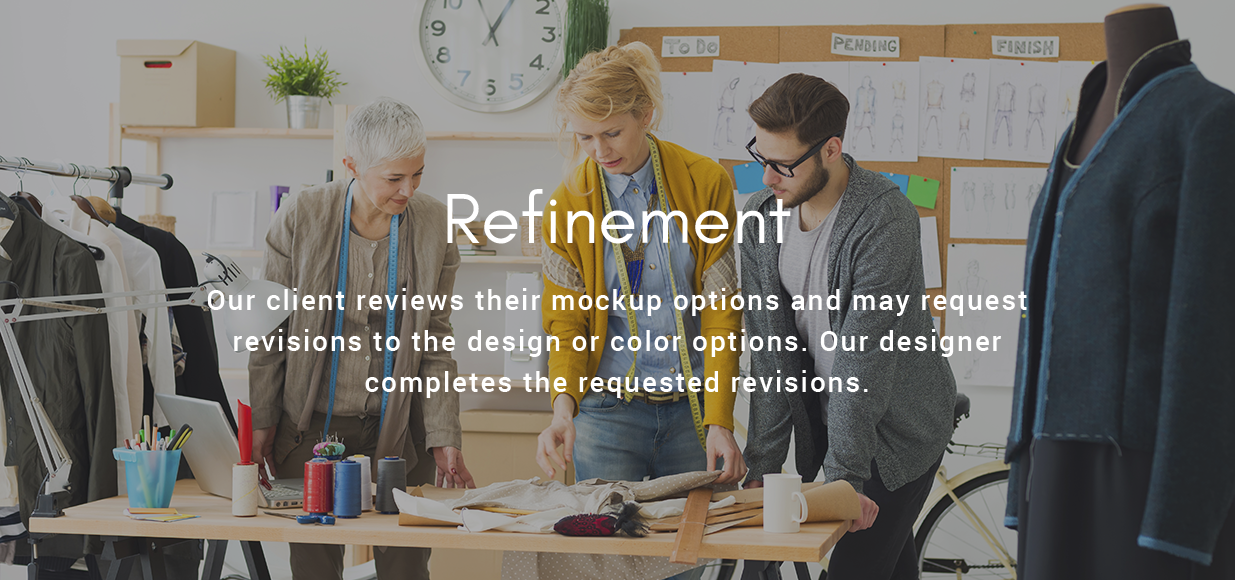

Design & Approval

Our New York fashion designer incorporates all design elements and ideas into the textile designs which are always authentic and created exclusively for each individual client and/or project. Our designer typically prepares six to eight draft designs which we forward on to our client. Following any requested revisions, it's time to get the manufacturing process underway in Italy or Asia. Client samples may be provided upon request, prior to product completion.

Manufacturing

Once all designs and product samples are approved by our client, our preferred manufacturer begins the process of manufacturing or finishing the fabric — whether it be creating the actual raw material, introducing specific requested textures, screen-printing to add the fabric designs, and/or preparing all materials for the product manufacturing process. Following the manufacturing process, our client receives their custom shipment.

Request more information or place an order...

Go behind the scenes at our most recent photo shoot...

Photo Credit: Jackie Jones Photography